Environmental Compliance & Emission Control

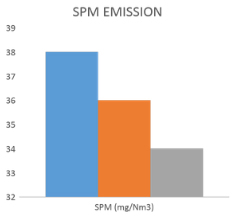

In December 2015, the MoEF&CC established new limits for water consumption and stack emissions, covering SOx, NOx, PM, and mercury from thermal power plants. Our existing units are already compliant with the new standards for mercury and PM. To meet the new SO2 emission standards, we are following the FGD implementation plan prepared by the CEA.

n our pursuit of environmental compliance, we've commissioned a De-Nox scheme in unit 1, supplied by GE, India, in October 2023, meeting NOx standards. The commissioning of unit 2 DE-Nox is currently underway, with completion expected by January '24.

DIL maintains air quality with three online monitoring stations and controls stack emissions using a central system. Their sophisticated chemical laboratory is equipped for water, waste, and air quality testing with modern instruments like pH meters and spectrophotometers.

DIL has taken various steps to control fugitive emissions on their plant premises, including the installation of a Dry Fog Dust Suppression system in coal handling areas, telescopic chutes in fly ash unloading areas, the development of a green belt around the coal stockyard to act as a natural wind shield, covering conveyors, employing rain guns and sprinklers in the coal yard, and installing an ash in coal analyzer for monitoring ash content during coal feeding, collectively enhancing environmental standards and reducing fugitive emissions.